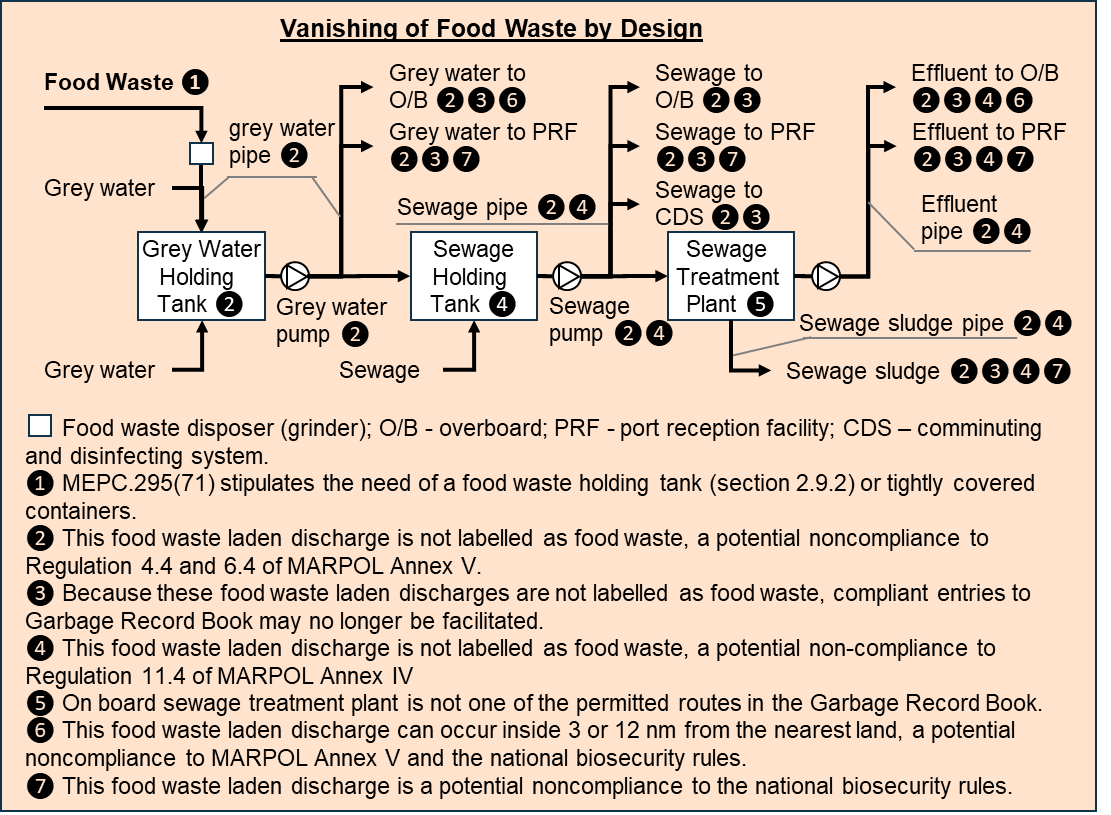

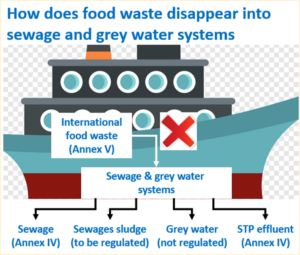

Connecting ship’s food waste to the sewage or greywater system and thus the sewage treatment plant of the vessel causes non-compliances to the MARPOL Convention and national biosecurity laws.

Recognising the pollution impact and the biosecurity risk of ship’s food waste, the IMO’s MARPOL Convention regulates its disposal, recording, and reporting requirements. MARPOL Annex V stipulates three legal food waste disposal routes. Ship’s sewage or greywater system is not one of them.

Connecting food waste to the sewage system of a vessel also violates Annex IV (sewage) of the MARPOL Convention. When waste streams of different MARPOL Annexes mix, the most stringent requirements shall apply. However, the discharges of the affected sewage and grey water systems are not labelled or managed as food waste. Food waste is made to disappear.

Food waste from international ships also carries biosecurity risks such as plant pests and diseases such as swine fever, rabies, and avian flu. Many countries have strict biosecurity regulations to protect their agricultural interests (table below). These national laws often prohibit the discharge of food waste into the territorial waters. They also stipulate strict procedures for storing, transporting and disposing such food waste when landed ashore. However, these national laws are violated when food waste is discharged into national waters and municipal sewers in disguise as effluent, grey water, sewage, or sewage sludge. Such non-compliant piping design is a non-compliance which can last the life of a ship. Wrongly approved by classification societies, it has been spreading across the shipping industry over the past decades.

The consequence can be far-reaching. The practices have violated the international and national laws, contributed to the poor performance status of sewage treatment plants onboard, undermined the credibility of the approval regimes, forced ship masters to authorise false entries in the Garbage Record Books, and damaged the reputation of the maritime industry especially when the aviation industry has managed to stay in compliance with the national biosecurity laws.

So far, no relevant authorities have aired their opinions or taken corrective actions. The shipping industry continues to be misguided by certain class rules. It may take an awful long time for the regulations to be effectively implemented. But there are signs of constructive change initiated by the industry.

The Cruise Lines International Association (CLIA) released an informative report in 2021 on the cruise industry’s commitment to responsible tourism practices and environmental technologies. It includes a case study of a liquid derivative generated from the food waste processing equipment. It stated that ‘CLIA members treat this liquid waste as food waste as governed by MARPOL Annex V Regulations 4 and 6 which set forth the maximum food particle size, discharge rates, and distance from the nearest land or ice-shelf when discharged’ [1]. This is a concrete step towards future-proofing compliant system design, installation, and operation.

| DEFINITIONS | KEY SPECIFICATIONS | LINKS |

|---|---|---|

| EU - ‘International catering waste (ICW)’ or Category 1 material of animal by-products. | To be stored, transported, processed and disposed in accordance with the requirements for Category 1 material. | https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02009R1069-20140101&from=EN; https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02011R0142-20190320 |

| US - ‘Garbage regulated because of movements outside the United States or Canada… within the previous 2-year period’. | Regulated garbage must be contained in tight, leak-proof covered receptacles during storage… and unloaded ‘under the direction of an APHIS inspector to an approved facility for incineration, sterilization, or grinding into an approved sewage system…’ | Title 7 CFR 330.400 -330.403 https://www.govinfo.gov/content/pkg/CFR-1998-title7-vol5/pdf/CFR-1998-title7-vol5-sec330-400.pdf; and https://www.govinfo.gov/content/pkg/CFR-2012-title9-vol1/pdf/CFR-2012-title9-vol1-sec94-5.pdf |

| Canada - ‘Ship’s refuse’ from outside Canada and the US. | To be stored in closed leakproof containers and removed at the first port of entry to approved facilities for incineration or sterilisation, or landfills for deep burial. | https://laws-lois.justice.gc.ca/eng/regulations/c.r.c.,_c._296/page-5.html#docCont |

| New Zealand - ‘Risk goods’. | While within New Zealand territorial waters, risk goods shall be secured onboard… and kept in a leakproof, vermin-, insect- and bird-proof container or room… | Craft Risk Management Standards for Vessels, MPI, New Zealand Government, 2018. Guidance Document to the CRMS for Vessels, MPI, New Zealand Government, 2017 |

| Australia - biosecurity waste | Australia has requirements for the collection, storage, and transport of this waste for acceptable disposal methods. | Australia Biosecurity Act https://www.agriculture.gov.au/biosecurity/legislation and https://www.agriculture.gov.au/biosecurity/avm/vessels. Management of biosecurity risks associated with transhipped ships stores. No. 2014–15/08, 2016. |