WHAT IS FLOCCULANT?

Flocculant is required for the operation of HAMANN HL-CONT Compact / HL-CONT Plus sewage treatment plants and HL-CONT Plus OceanCruise / HL-CONT Plus RiverCruise advanced wastewater treatment systems. The flocculant supports the Dissolved Air Flotation (DAF) process, the main sewage treatment technology applied in these plants. Better flocculation results in a better treatment performance of the sewage treatment plant. HAMANN BlueFloc has been developed to the specifications of the HAMANN R&D team to optimise flocculation and has been proven in our test facilities. It is produced in Germany to HAMANN quality standards.

ORDER HAMANN BlueFloc

PHONE +49 (0)4165 22 11 400

E-MAIL spares@hamannag.com

KEY FACTS HAMANN BlueFloc FLOCCULANT

HIGH PERFORMANCE FLOCCULANT FOR SEWAGE TREATMENT PLANTS

Flocculant is essential for the treatment process HAMANN sewage treatment plants and advanced wastewater treatment systems applied and is required for their operation.

SUPPORTS TSS/COD/BOD REDUCTION

The flocculant is used in the process step, where TSS (Total Suspended Solids), COD (Chemical Oxygen Demand) and BOD (Biological Oxygen Demand) are reduced by Dissolved Air Flotation (DAF).

ENHANCES FLOCCULATION & CONTRIBUTES TO THE TREATMENT PERFORMANCE

HAMANN BlueFloc is designed to optimise the flocculation during the Dissolved Air Flotation (DAF) process and thus optimise the treatment performance achieved in this process step.

READY-TO-USE MIXTURE OF ALUMINIUMBASED FLOCCULANT AND POLYMER

HAMANN BlueFloc is an aluminium-based mix with polymers and ready to use right out of the container.

FLOCCULANT IS CRITICAL FOR THE SEWAGE TREATMENT PERFORMANCE

HAMANN sewage treatment plants and advanced wastewater treatment systems apply our Dissolved Air Flotation (DAF) technology as one of several steps in the sewage treatment process. To support the flotation process, a flocculant is needed. HAMANN BlueFloc is designed to optimise the flocculation and thus optimise the treatment performance achieved in this process step.

WHAT FLOCCULANT FOR SEWAGE TREATMENT PLANTS DOES

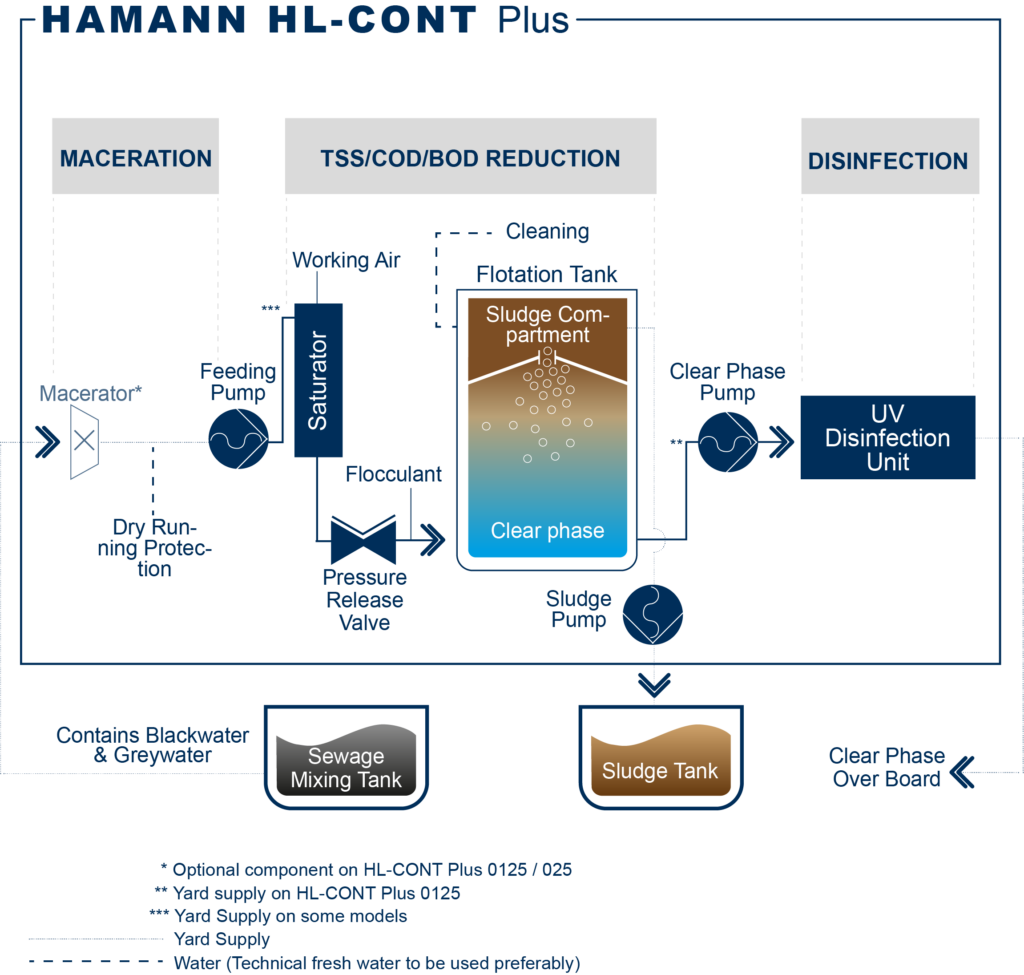

Let’s take a look at the treatment process applied in our HL-CONT Plus range of sewage treatment plants. The complete process incorporates four steps: Preparation of the sewage mix, maceration, TSS/COD/BOD reduction and disinfection.

The flocculant is used in the third process step, where TSS (Total Suspended Solids), COD (Chemical Oxygen Demand) and BOD (Biological Oxygen Demand) are reduced by Dissolved Air Flotation (DAF).

FLOCCULANT SUPPORTS TSS/COD/BOD REDUCTION

By means of our Dissolved Air Flotation (DAF) technology, the suspended solids (TSS) are separated and the chemical (COD) and biological (BOD) oxygen demand is reduced. The sewage is enriched with air under a pressure in the saturator. After being discharged into the flotation tank through the pressure release valve, the excess air forms micro bubbles. The flocculant is added in order to let air bubbles and suspended particles form larger flakes. These flakes float upwards, creating a sludge foam on the surface and leaving the clear phase in the lower part of the flotation tank. The sludge foam spills into the sludge compartment and is subsequently fed into the ship‘s sludge tank.

To learn more about the treatment technology applied in our sewage treatment plants and advanced wastewater treatment systems, please visit the product pages:

- HL-CONT Compact sewage treatment plants

- HL-CONT Plus sewage treatment plants

- HL-CONT Plus OceanCruise advanced wastewater treatment systems

- HL-CONT Plus RiverCruise advanced wastewater treatment systems