Grease separators are crucial for the performance of sewage systems. Fats, oils and grease, in short: F.O.G., have a negative impact on the performance of the sewage system. Pipelines and sensors are blocked or sealed by grease deposits within a short time. In holding tanks, grease accelerates the formation of hydrogen sulphide, a toxic and highly odorous gas. Hydrogen sulphide can lead to the formation of sulphuric acid, which then attacks the substance in the pipes. In addition, the purification performance of the sewage treatment plant is severely impaired. Fats, oils and grease mainly get into the sewage via food residues in the galley water. Therefore, all drainage from kitchen areas, i.e. from sinks and dishwashers, or residual water from food waste treatment systems should pass through a grease separator. Only after this treatment, it may be considered as greywater and discharged into a holding tank. Food waste itself must always be treated separately from sewage, as it falls under MARPOL Annex V.

CONTACT OUR SALES TEAM

PHONE +49 (0)4165 22 11 100

E-MAIL sales@hamannag.com

KEY FACTS GS Compact

REDUCED RISK OF SEWAGE SYSTEM BLOCKAGES AND H2S-FORMATION

Fats, oils and greases can block pipes and sensors. They also accelerate the formation of hydrogen sulohide (H2S) and subsequently sulphuric acid (H2SO4). HAMANN GS Compact grease separators reduce these risks by removing fats, oils and greases from the galley water before it enters the greywater system.

ROBUST & RELIABLE

HAMANN grease separators are completely made of stainless steel for maximum robustness, durability and reliability.

EASE OF OPERATION & LOW MAINTENANCE

HAMANN GS Compact grease separators work with gravity separation. There are no moving mechanical parts inside the plant and no additives are needed. Operation is extremely easy and maintenance requirements are minimal.

TÜV RHEINLAND CERTIFIED

HAMANN grease separators are DIN certified by TÜV Rheinland according to DIN EN 1825-1, DIN EN 1825-2 and DIN EN 4040.

HAMANN GS Compact MAIN SPECS

PLEASE NOTE: This information is not to be used for design purposes. Subject to change without notice! The detailed technical specifications and all information on the scope of delivery are given in the product specifications of the respective plant model. Please contact our sales team via sales@hamannag.com.

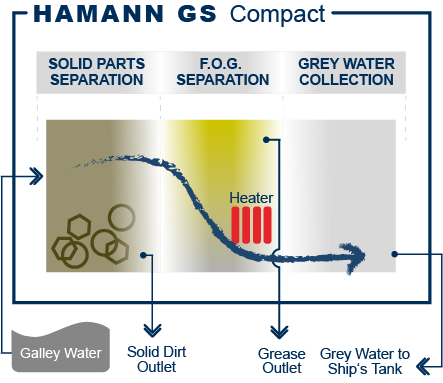

HAMANN GS Compact GREASE SEPARATION TECHNOLOGY

HAMANN grease separators work exclusively according to the principle of gravity separation without mechanical parts or additives. Solid food residues are first separated from the waste water by gravity. Then, the fats and oils, which are lighter than water are collected at the top of the separation chamber of the grease separator. From there the collected fats and oils can be drained. A built-in heater keeps the fat liquid so that it can be drained more easily. Separated fats and oils from the grease separator, as well as solid food residues are transfered into external containers via the outlets provided for this purpose and disposed of ashore.