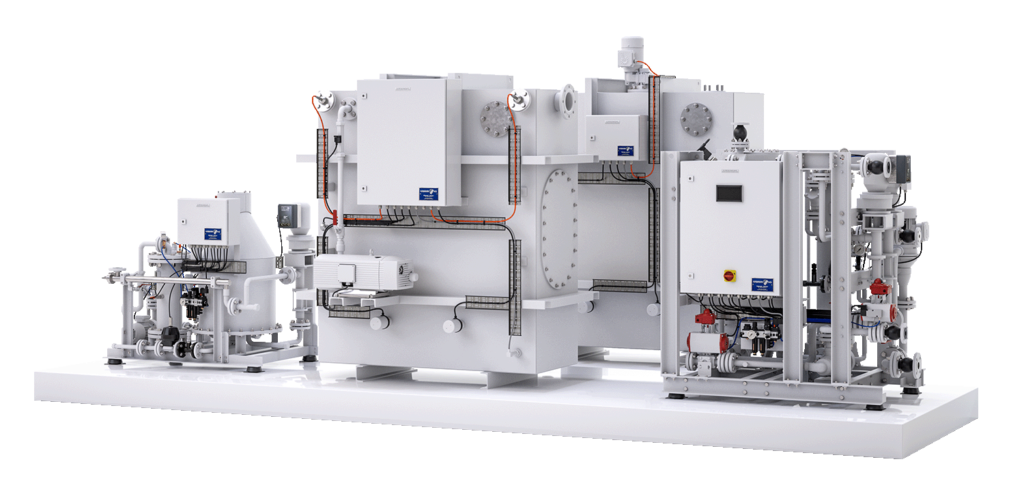

The HAMANN HL-CONT Plus OceanCruise range of advanced wastewater treatment systems (AWTS) are designed to meet or exceed the highest current standards for sewage and greywater discharge. These advanced wastewater treatment systems are suitable for ships operating in the waters of Alaska or the Baltic Sea (MARPOL Annex IV special area). Combining our physical and biological treatment technologies, HL-CONT Plus OceanCruise systems eliminate the need for filters and membranes. Another key feature is the modular design.

HL-CONT Plus OceanCruise plants consist of four separate modules, which can be installed apart from each other, even on different decks. This gives tremendous flexibility when it comes to fitting a sewage system into a hull. Moreover, ship’s tanks may be converted to become the biological treatment modules. The footprint of a HAMANN HL-CONT Plus OceanCruise system can be significantly smaller than that of a comparable system from other manufacturers.

KEY FACTS HL-CONT Plus OceanCruise AWT SYSTEMS

ALASKA & BALTIC SEA COMPLIANT

HAMANN HL-CONT Plus OceanCruise advanced wastewater treatment systems (AWTS) comply with the strictest regulations on sewage discharge in place today: The IMO‘s MEPC.227(64) section 4.2 regarding the Baltic Sea as MARPOL Annex IV special area as well as US 33 CFR 159 Subpart E regarding the waters of the state of Alaska.**

SMALL FOOTPRINT

Due to our technology and design, the footprint of HAMANN HL-CONT Plus OceanCruise advanced wastewater treatment systems (AWTS) can be significnatly smaller than comparable

systems from other manufacturers. Ship tanks can be converted to MBBR modules which further reduces the already small footprint of the system.

COMBINED BLACK WATER & GREY WATER

TREATMENT

As all HAMANN plants, HL-CONT Plus OceanCruise systems are designed to treat black water and grey water as a sewage mixture in the same process. This benefits the performance

and reliability of the sewage treatment system as well as the environment.

EASE OF OPERATION & LOW MAINTENANCE

Routine functions on HAMANN plants are fully automatic and no specialised skills are required for daily operation. Our technology eliminates the need for filters and membranes, which would require a lot of work for regular cleaning and replacement. The open design of the DAF units allows instant access to all components for inspection and service purposes. Routine maintenance on HAMANN plants can be carried out quickly and easily by the crew on board.

RETROFIT-FRIENDLY MODULAR DESIGN

Each of the four separate modules of a HAMANN HL-CONT Plus OceanCruise system is only a fraction of the size of a comparable single block plant. Therefore, it is much easier to find the space to install them, most particularly on an existing vessel. In addition, the DAF units of HAMANN systems can be delivered dismantled for assembly at the location of installation on board the vessel. A huge benefit in retrofit projects, where this feature can often spare cutting an opening into the hull, saving a lot of time and money.

HL-CONT Plus OceanCruise AWTS MAIN SPECS

PLEASE NOTE: This information is not to be used for design purposes. Subject to change without notice! The detailed technical specifications and all information on the scope of delivery are given in the product specifications of the respective plant model. Please contact our sales team via sales@hamannag.com.

* Basic measurements of main unit, excluding MBBR modules for biological treatment (project specific)

** For the latest information on the certification of specific models, please contact us or check gisis.imo.org for IMO certificates, cgmix.uscg.mil for USCG certificates and mared.org for EU MED certificates.

HL-CONT Plus OceanCruise TREATMENT TECHNOLOGY

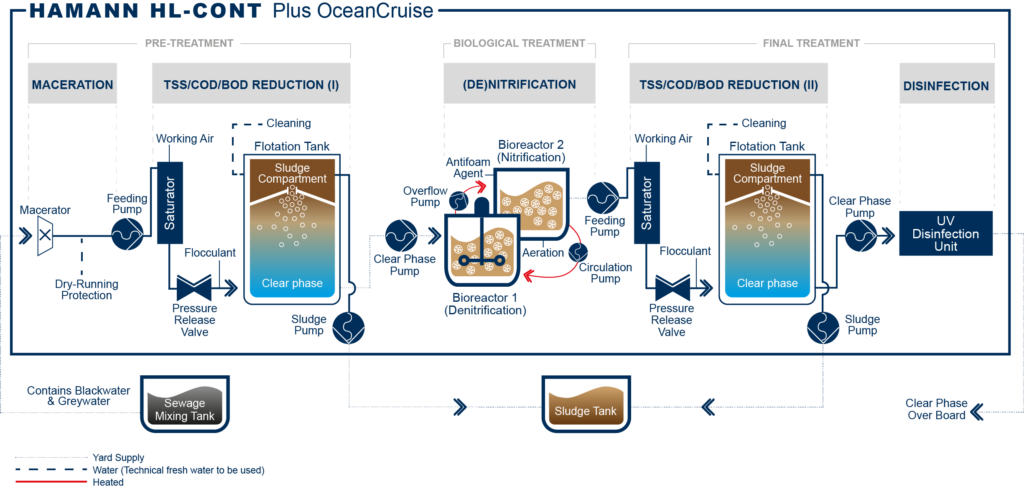

PREPARATION: CREATING THE SEWAGE MIX

HAMANN HL-CONT Plus OceanCruise plants are designed to process both blackwater and greywater as a sewage mixture. This mixture is created in the sewage mixing tank from which it is pumped into the sewage treatment plant. Depending on the tank configuration on board, greywater and/or blackwater are transferred into the sewage mixing tank to create the sewage mixture. When the filling level in the sewage mixing tank reaches a predefined level, the feeding pump of the sewage treatment plant starts to operate and the treatment process is initiated.

PRE-TREATMENT

The sewage mix from the sewage mixing tank is first run through a macerator to chop up solid and fibrous components. By means of our Dissolved Air Flotation (DAF) technology we separate the suspended solids (TSS) and reduce the chemical (COD) and biological (BOD) oxygen demand. With the addition of a flocculant, the solids create a sludge foam on the surface, leaving the clear phase in the lower part of the flotation tank. The sludge foam spills into the sludge compartment and is subsequently fed into the ship‘s sludge tank.

BIOLOGICAL TREATMENT

The pre-treated sewage is drained into the two-stage biological treatment of the HL-CONT Plus OceanCruise system, consisting of two Moving Bed Biofilm Reactors (MBBR). Circulating between the denitrification and nitrification stages, bacteria metabolize the nitrogen compound in the sewage.

FINAL TREATMENT

Since the bacterial processes in the biological treatment also produces biomass, the solids have to be removed in the second DAF unit. The flocculant used in this process also removes the phosphorus.

The already largely purified sewage is finally exposed to UV radiation to degrade the DNA of bacteria and microorganisms, rendering them incapable of reproducing and infecting. After this finishing step, the treated sewage from the HL-CONT Plus OceanCruise plant is safe to be discharged overboard (if permitted).

3 MORE REASONS TO CHOOSE HAMANN

OUTSTANDING PRE-SALES & AFTER-SALES CUSTOMER SUPPORT

We are the specialist partner for sewage systems since almost 50 years. We are at our customer‘s side from the planning stage to operation. With over 40 sales agents and service partners in the HAMANN GLOBAL NETWORK we provide customer support and technical field service around the globe.

TAILORED SOLUTIONS

We listen carefully to what the customer’s requirements are. We provide expert consultancy on sewage and greywater systems on board ships. And then we offer the customised system that best suits the customer‘s project. Providing customer specific solutions is part of HAMANN‘s DNA.

QUALITY MADE IN GERMANY

All our products are designed and made in Hollenstedt, Germany, according to our accredited ISO 9001 quality management system. We only use high quality materials and components from renowned manufacturers. Since 1972, we have supplied sewage treatment equipment to more than 5500 superyachts, ferries, cruise ships, commercial and naval vessels all over the world.

CONTACT OUR SALES TEAM

PHONE +49 (0)4165 22 11 100

E-MAIL sales@hamannag.com