Anaerobic conditions and sedimentation are two problems associated with the storage of untreated sewage, blackwater and sewage sludge. Anaerobic conditions develop due to natural oxygen consuming biological processes within the sewage. As a result, hydrogen sulphide (H2S) or even sulphuric acid (H2SO4) may form. The first is an extremely smelly and potentially lethal gas, the latter can erode the substance of the plant, the piping and ultimately the ship’s structure. Sedimentation occurs because of the solid particles and suspended solids, e.g. from toilet paper or hairs, in the sewage. As they are heavier than water, they tend to settle and concentrate in the lower layers of the sewage in a holding tank. When the “thick” lower layers are fed into the sewage treatment plant, they may cause clogging of valves, sensors and pipes of the plant. Both anaerobic conditions and sedimentation in the sewage mix lead to significantly reduced treatment performance of the sewage treatment plant. Therefore, both are to be avoided.

OUR SEWAGE CONDITIONING PRODUCTS

CONTACT OUR SALES TEAM

PHONE +49 (0)4165 22 11 100

E-MAIL sales@hamannag.com

KEY FACTS HAMANN SEWAGE CONDITIONING SYSTEMS

PREVENTS SMELLY AND TOXIC GASES

HAMANN TA tank aeration systems ensure a constant supply of oxygen in sewage holding tanks to prevent the formation of hydrogen sulphide (H2S) or subsequently sulphuric acid (H2SO4).

REDUCED RISK OF BLOCKAGES OF PIPES, SENSORS AND VALVES

Pumping sewage concentrated by sedimentation into the sewage treatment plant can result in blockages of pipes, sensors and valves, which will reduce the performance of the plant or cause it to fail alltogether. HAMANN TA tank aeration systems counteract sedimentation of solid particles through the movement in the tank contents induced by blowing air into the tank.

PROMOTION OF ACTIVE BIOLOGICAL PROCESSES

The constant supply of oxygen also assists the active biological processes in the sewage. This is the natural way of sewage treatment. It is a form of natural pre-treatment that contributes to the performance of the sewage system on board.

KEEPS SEWAGE SLUDGE PUMPABLE

Sewage sludge stored in a holding tank tends to rapidly develop sedimentation and will then no longer be pumpable. A HAMANN TC tank circulation systems effectively prevents sedimentation and keeps sludge pumpable at all times.

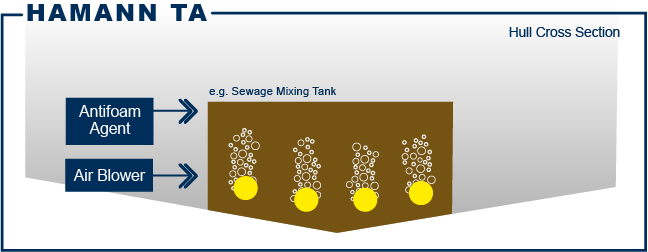

HAMANN TA

TANK AERATION SYSTEMS

The longer untreated sewage or black water are stored in holding tanks, the more likely it is for anaerobic conditions to develop. Natural biological processes within the sewage consume oxygen and this consumption needs to be compensated. Anaerobic conditions can lead to the formation of hydrogen sulphide (H2S) or even sulphuric acid (H2SO4). The first is an extremely smelly and potentially lethal gas, the latter can erode the substance of the plant, the piping and ultimately the ship’s structure. For this reason, the IMO Maritime Safety Committee (MSC) Circular 648 (Guidelines for the operation, inspection and maintenance of ship sewage systems) states that storage tanks without active aeration should be monitored very closely.

A HAMANN TA tank aeration system compensates the oxygen consumed by biological processes within the sewage by supplying fresh oxygen. This effectively prevents the build-up of hydrogen sulphide (H2S) in blackwater holding tanks. The constant supply of oxygen also assists the active biological processes in the sewage. This is the natural way of sewage treatment. It is a form of natural pre-treatment that contributes to the performance of the sewage system on board. Blowing air into the tank also creates movement in the tank contents. That helps to counteract sedimentation of solid particles. We recommend HAMANN TA systems for all holding tanks containing blackwater.

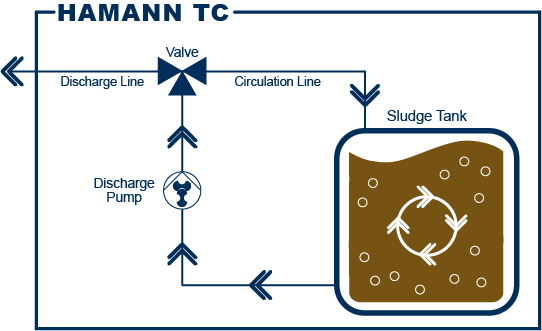

HAMANN TC

TANK CIRCULATION SYSTEMS

Sewage sludge basically consists of the solid particles and suspended solids extracted from the sewage in the treatment process. Therefore, it already has a thickened consistency, but is still pumpable. Sewage sludge stored in a holding tank tends to rapidly develop sedimentation. Within a very short period of time, the lower layers in the sludge tank will then no longer be pumpable. To be discharged, the contents then would have to be manually removed from the tank, requiring a considerable amount of time and effort. To avoid having to execute this most unpleasant task, a HAMANN TC sludge circulation system should be installed. It constantly circulates the sludge in the holding tank, preventing sedimentation and keeping it in pumpable condition at all times.