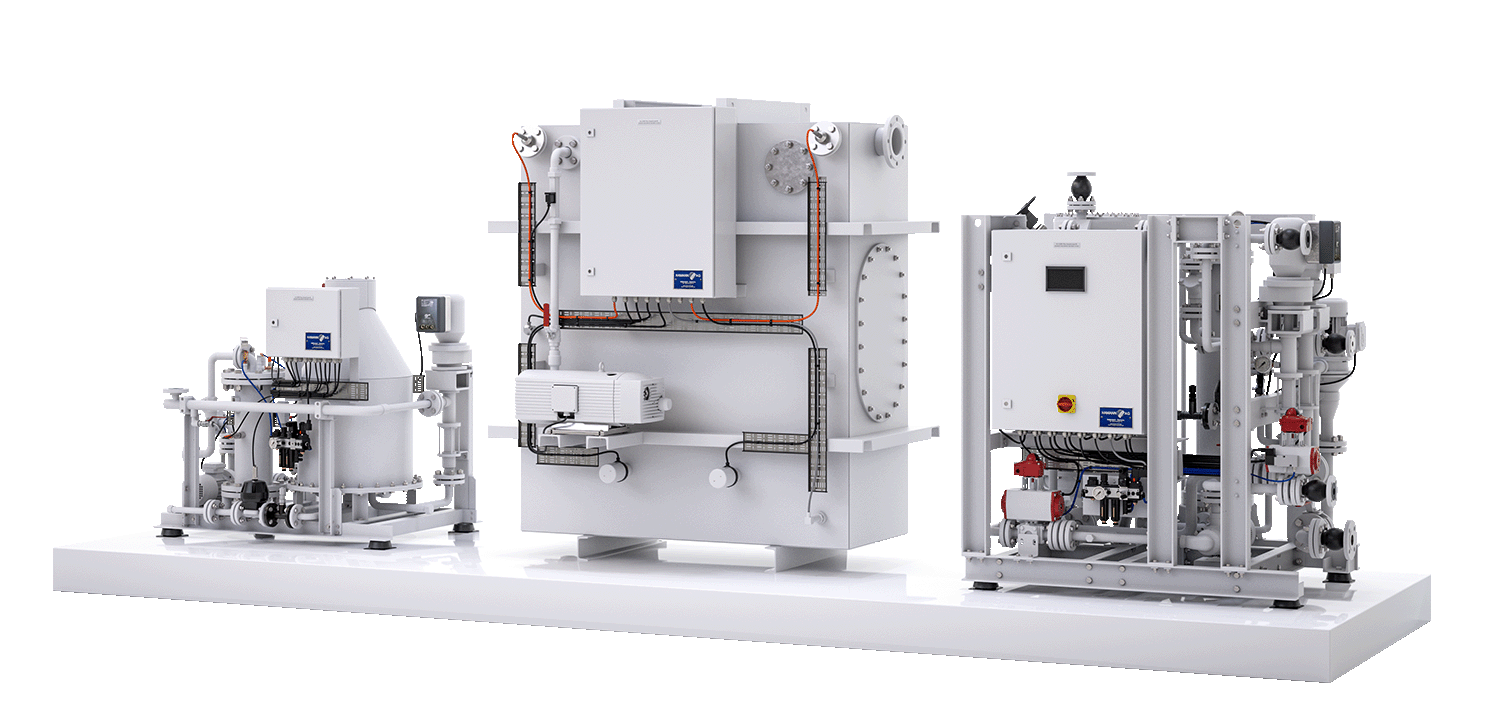

The HAMANN HL-CONT Plus RiverCruise range of advanced wastewater treatment systems (AWTS) is specifically designed to meet the technical requirements of Commission Directive 2012/49/EU on sewage and greywater discharge for inland waterway vessels. Combining our physical and biological treatment technologies, HL-CONT Plus RiverCruise systems eliminate the need for filters and membranes. Another key feature is the modular design. HL-CONT Plus RiverCruise plants consist of three separate modules, which can be installed apart from each other, even on different decks. This gives tremendous flexibility when it comes to fitting a sewage system into a hull. Moreover, ship’s tanks may be converted to become the biological treatment modules. The footprint of a HAMANN HL-CONT Plus RiverCruise system can be significantly smaller than that of a comparable system from other manufacturers.

CONTACT OUR SALES TEAM

PHONE +49 (0)4165 22 11 100

E-MAIL sales@hamannag.com

KEY FACTS HL-CONT Plus RiverCruise AWT SYSTEMS

EU CERTIFIED FOR INLAND NAVIGATION

HAMANN HL-CONT Plus RiverCruise Advanced Wastewater Treatment Systems (AWTS) are certified to the Euopean Union‘s Commission Directive 2012/49/EU (ES-TRIN) regarding technical requirements for inland waterway vessels.

SMALL FOOTPRINT

Due to our technology and design, the footprint of HAMANN HL-CONT Plus RiverCruise advanced wastewater treatment systems (AWTS) can be significantly smaller than comparable systems from other manufacturers.

COMBINED BLACK WATER & GREY WATER TREATMENT

As all HAMANN plants, HL-CONT Plus RiverCruise systems are designed to treat black water and grey water as a sewage mixture in the same process. This benefits the performance and reliability of the sewage treatment system as well as the environment.

RETROFIT-FRIENDLY MODULAR DESIGN

Each of the three separate modules of a HAMANN HL-CONT Plus RiverCruise system is only a fraction of the size of a comparable single block plant. Therefore, it is much easier to find the space to install them, most particularly on an existing vessel. In addition, the DAF units of HAMANN systems can be delivered dismounted for assemby at the location of installation on board the vessel. A huge benefit in retrofit projects, where this feature can often spare cutting an opening into the hull, saving a lot of time and money.

EASE OF OPERATION & LOW MAINTENANCE

Routine functions on HAMANN plants are fully automatic and no specialised skills are required for daily operation. Our technology eliminates the need for filters and membranes, which would require a lot of work for regular cleaning and replacement. Routine maintenance on HAMANN plants can be carried out quickly and easily by the crew on board. The open design of the DAF units allows instant access to all components for inspection and service purposes.

HL-CONT PLUS RIVERCRUISE MAIN SPECS

PLEASE NOTE: This information is not to be used for design purposes. Subject to change without notice! The detailed technical specifications and all information on the scope of delivery are given in the product specifications of the respective plant model. Please contact our sales team via sales@hamannag.com.

* Basic measurements of main unit, excluding MBBR module for biological treatment (project specific)

HL-CONT PLUS RIVERCRUISE TECHNOLOGY

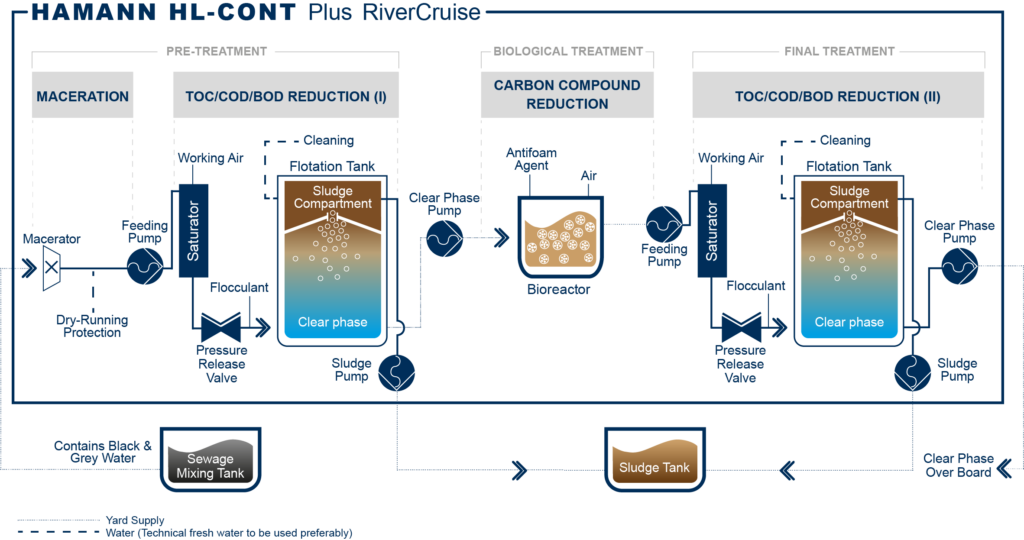

PREPARATION: CREATING THE SEWAGE MIX

HAMANN HL-CONT Plus RiverCruise plants are designed to process both blackwater and greywater as a sewage mixture. This mixture is created in the sewage mixing tank from which it is pumped into the sewage treatment plant. Depending on the tank configuration on board, greywater and/or blackwater are transferred into the sewage mixing tank to create the sewage mixture. When the filling level in the sewage mixing tank reaches a predefined level, the feeding pump of the sewage treatment plant starts to operate and the treatment process is initiated.

PRE-TREATMENT

The sewage mix from the sewage mixing tank is first run through a macerator to chop up solid and fibrous components. By means of our Dissolved Air Flotation (DAF) technology we separate the suspended solids (TSS) and reduce the chemical (COD) and biological (BOD) oxygen demand. With the addition of a flocculant, the solids create a sludge foam on the surface, leaving the clear phase in the lower part of the flotation tank. The sludge foam spills into the sludge compartment and is subsequently fed into the ship‘s sludge tank.

BIOLOGICAL TREATMENT

The pre-treated sewage is drained into the Moving Bed Biofilm Reactor (MBBR) of the HL-CONT Plus RiverCruise system. Under permanent aeration and at a controlled temperature, bacteria metabolise the carbon compound (TOC) in the sewage.

FINAL TREATMENT

Since the bacterial processes in the biological treatment also produces biomass, the solids have to be removed in the second DAF unit. The flocculant used in this process also removes the phosphorus. The treated sewage effluent from the HL-CONT Plus RiverCruise plant is safe to be discharged overboard (if permitted).