PREPARATION: CREATING THE SEWAGE MIX

HAMANN sewage treatment plants (STP), or marine sanitation devices (MSD) and advanced wastewater treatment systems (AWTS) are designed to process both blackwater and greywater as a sewage mixture. This mixture is created in the sewage mixing tank from which it is pumped into the sewage treatment plant. Depending on the tank configuration on board, greywater and/or blackwater are transferred into the sewage mixing tank to create the sewage mixture. When the filling level in the sewage mixing tank reaches a predefined level, the feeding pump of the sewage treatment plant starts to operate and the treatment process is initiated.

HAMANN SEWAGE TREATMENT TECHNOLOGY FOR GENERAL APPLICATIONS

MACERATION

The sewage mixture from the sewage mixing tank is first run through a macerator to chop up solid and fibrous components.

TSS/COD/BOD REDUCTION

By means of our Dissolved Air Flotation (DAF) technology, HAMANN HL-CONT PLUS sewage treatment plants separate the suspended solids (TSS) and reduce the chemical (COD) and biological (BOD) oxygen demand. The sewage is enriched with air under a pressure in the saturator. After being discharged into the flotation tank through the pressure release valve, the excess air forms micro bubbles. A flocculant is added in order to let air bubbles and susupended particles form larger flakes. These flakes float upwards, creating a sludge foam on the surface and leaving the clear phase in the lower part of the flotation tank. The sludge foam spills into the sludge compartment and is subsequently fed into the ship‘s sludge tank.

DISINFECTION

The already largely purified sewage is finally exposed to UV radiation to degrade the DNA of bacteria and microorganisms, rendering them incapable of reproducing and infecting. After this finishing step, the treated sewage from the HAMANN HL-CONT PLUS sewage treatment plant is safe to be discharged overboard (if permitted).

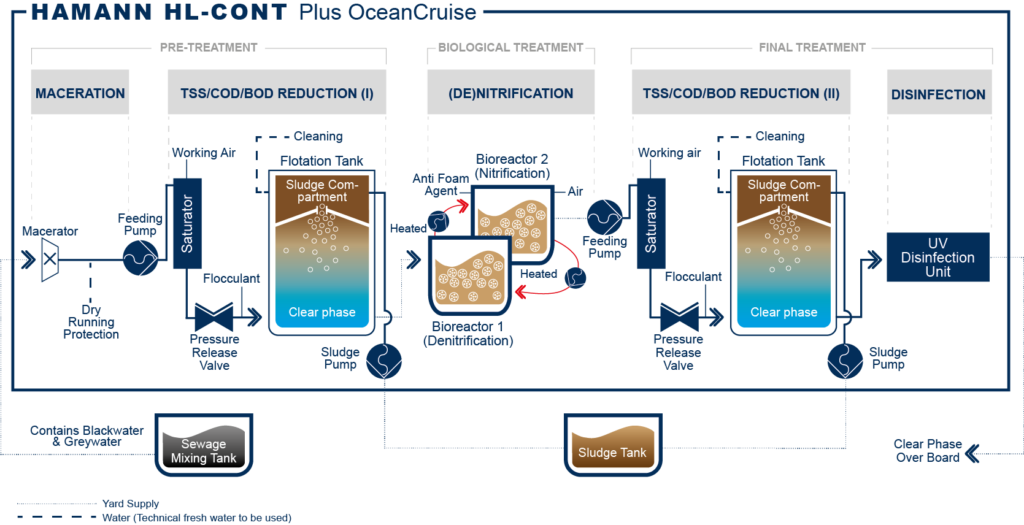

HAMANN SEWAGE TREATMENT TECHNOLOGY FOR MARPOL ANNEX IV SPECIAL AREAS AND ALASKAN WATERS

PRE-TREATMENT

The sewage mix from the sewage mixing tank is first run through a macerator to chop up solid and fibrous components. By means of our Dissolved Air Flotation (DAF) technology we separate the suspended solids (TSS) and reduce the chemical (COD) and biological (BOD) oxygen demand. With the addition of a flocculant, the solids create a sludge foam on the surface, leaving the clear phase in the lower part of the flotation tank. The sludge foam spills into the sludge compartment and is subsequently fed into the ship‘s sludge tank.

BIOLOGICAL TREATMENT

The pre-treated sewage is drained into the two-stage biological treatment of the HL-CONT PLUS OceanCruise system, consisting of two Moving Bed Biofilm Reactors (MBBR). Circulating between the denitrification and nitrification stages, bacteria metabolize the nitrogren compound in the sewage.

FINAL TREATMENT

Since the bacterial processes in the biological treatment also produces biomass, the solids have to be removed in the second DAF unit. The flocculant used in this process also removes the phosphorus.

The already largely purified sewage is finally exposed to UV radiation to degrade the DNA of bacteria and microorganisms, rendering them incapable of reproducing and infecting. After this finishing step, the treated sewage from the HL-CONT PLUS OceanCruise plant is safe to be discharged overboard (if permitted).

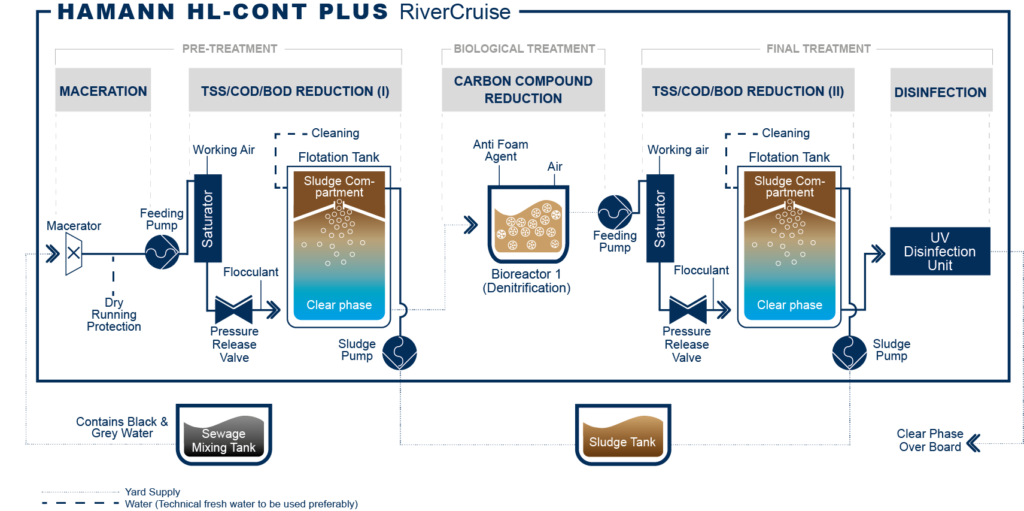

HAMANN SEWAGE TREATMENT TECHNOLOGY FOR INLAND NAVIGATION

PRE-TREATMENT

The sewage mix from the sewage mixing tank is first run through a macerator to chop up solid and fibrous components. By means of our Dissolved Air Flotation (DAF) technology we separate the suspended solids (TSS) and reduce the chemical (COD) and biological (BOD) oxygen demand. With the addition of a flocculant, the solids create a sludge foam on the surface, leaving the clear phase in the lower part of the flotation tank. The sludge foam spills into the sludge compartment and is subsequently fed into the ship‘s sludge tank.

BIOLOGICAL TREATMENT

The pre-treated sewage is drained into the Moving Bed Biofilm Reactor (MBBR) of the HL-CONT PLUS RiverCruise system. Under permanent aeration and at a controlled temperature, bacteria metabolise the carbon compound (TOC) in the sewage.

FINAL TREATMENT

Since the bacterial processes in the biological treatment also produces biomass, the solids have to be removed in the second DAF unit. The flocculant used in this process also removes the phosphorus. The already largely purified sewage is finally exposed to UV radiation to degrade the DNA of bacteria and microorganisms, rendering them incapable of reproducing and infecting. The treated sewage effluent from the HL-CONT PLUS RiverCruise plant is safe to be discharged overboard (if permitted).